Stick welding different workpiece thicknesses can be tricky, especially if the welder is a relative newcomer to Shielded Metal Arc Welding (SMAW). It’s a technique that’s popular and fairly simple to master, that’s true enough, but it’s also a process that generates copious quantities of heat. As any welder knows, too much thermal energy is the enemy of thin metal welding. Then there’s the selection of the right “stick” electrode, which will also impact weld penetration depth.

There’s no doubt about it, although stick welding has been around for a long time, welders can’t afford to ignore workpiece thickness.

Armed for Success: Stop and Consider Electrode Selection

A Tooliom Tl-195S Stick Welding Machine is selected. It’s a dual-voltage device, so it’ll operate on regular domestic 110-Volt or on higher output 220-Volts. The controls are basic, yet they’ll accomplish just about any job a stick welding professional will encounter. Bottom of the front panel, there’s the positive (+) connector on the left and the negative (-) connector to the right. Further identifying those two cable plugin ports, the positive port is red and the negative is black.

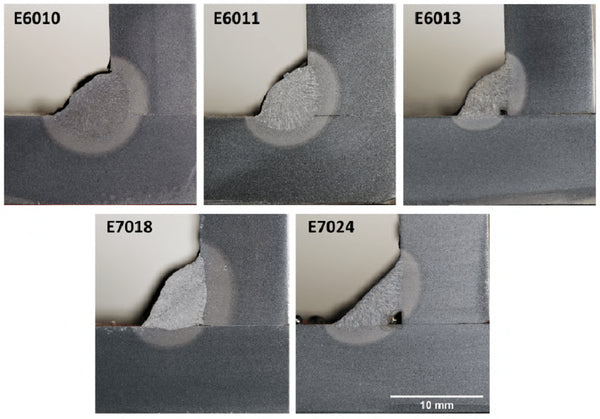

Here’s a small selection of coded stick electrodes and how their chemical compositions affect workpiece thickness welding techniques:

Thin Metal:

E6010 - Wrapped in a cellulose coating. Supports high force arc welding, so the weld bead remains narrow and focused. Expect good weld pool penetration while reducing excessive heat output.

E6013 - Excellent weld bead appearance is showcased. The general-purpose stick electrode is also a natural fit for thinner welding applications. Higher than average arc stability ratings minimize burnthrough.

Thick Metal nominees:

E7018 - Deposits a good quality weld with deep penetration, thus ensuring root fusion. Of relevance to industrial strength welding jobs, the rods produce thicker welds and have a higher tensile, plus a chemistry that reduces hydrogen embrittlement.

E6011 - Utilized on moderately thick welds. The electrodes make a good bridge for those jobs that lie between thin and thick metal work. It’s a compelling choice for general fabrication work. Features a high arc force.

Source: https://www.researchgate.net/figure/Macrographs-of-the-welds-with-120-A_fig3_357092340

It’s worth noting that these are not hard-and-fast rules. They’re guidelines. E6010 electrodes do work well on thinner welds, but they’re versatile, to the point that a rod of high penetrating E6010 can weld thicker metals, too. And that’s the case with many electrodes. Consult the equipment manual, the electrode seller, and any relevant data tables for more advice. And remember, everything from the flux thickness to the overall diameter of the rod will have an effect on welding metals of various thicknesses.Optimizing Equipment Setup for Workpiece Thickness

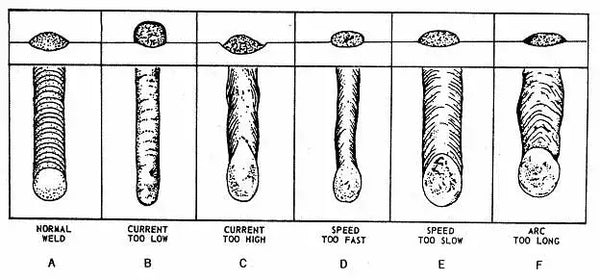

The selection of the desired stick welding electrode prepares the would-be sharp end of the welding process. The weld bead will fluidize and penetrate shallowly or deeply, it’ll cool and solidify in such a way that a solid joint is achieved, and it’ll have a smooth, uniform appearance that’s indicative of a high-quality weld. Away from the heat zone, welders use amperage control to tune arc characteristics. For thickness delineated setups, a lower amperage is desirable when working on thin metal parts. The opposite is also true; by upping the current, the stick core and coating melt faster and penetrate deeper.

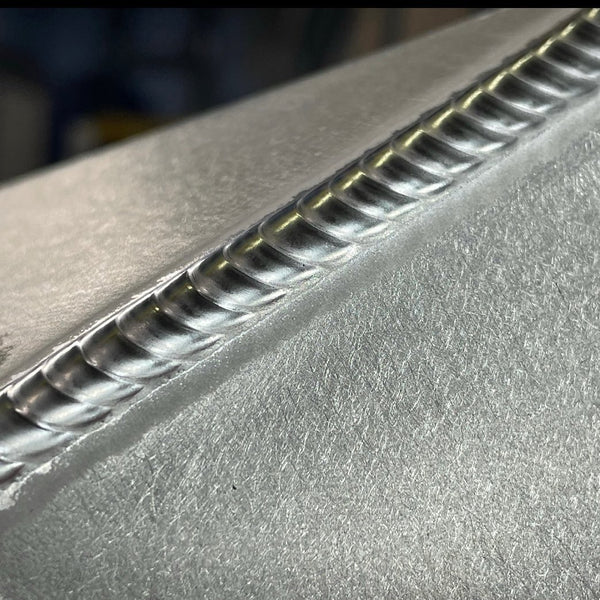

Photo by @weldd1 from TikTok

Pro welders are able to fine tune the amperage by feel. They not only select the right electrode for the gauge of metal being worked upon, they can also pick the right stick diameter and current setting too. For lesser mortals, meaning beginners and intermediate welders, there are recommended settings and amperage tables to refer to when entering control settings. The same information can often be found in stick electrode datasheets.

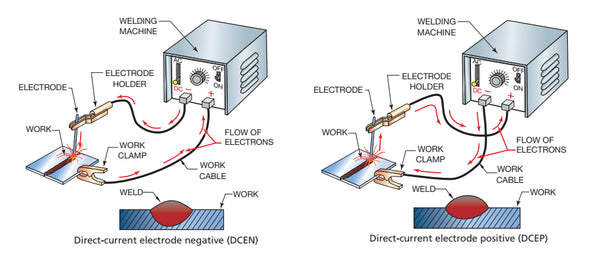

Just as an addendum, do refer to the manual of the Tooliom TL-195S if problems are encountered during a stick welding job. There’s a troubleshooting section at the back of the manual, plus a set of welding polarity guidelines on the product page. E6010, for example, should be configured as DCEN (Direct Current Electrode Positive). Opting instead for an E7018 electrode, a match that’ll suit a heavy gauge project, DCEP (Direct Current Electrode Positive) is selected. This might be stating the obvious, but it’s the electrode holding cable and ground cable that are swapped over at the output terminals to achieve this reversal of polarity.

DCEN Vs. DCEP

Source: https://amarineblog.com/2019/09/03/welding-current-types-dcen-dcep-ac/

Let’s talk in real world terms for a moment. Stick welding is popular for a good reason. It’s a technique that’s been around for decades. Still, thinking about 20-Amps and more, that’s a lot of power to control. It’s a challenge, especially when welding thin sections, to control that welding power. Additionally, with other welding techniques, there are ways of further refining the process, such as pulsed current control. That’s a rare feature at the moment in stick welding. This leaves welders relying on smart equipment settings. One such feature is a fast, easy arc start. The Tooliom Stick TL-195S machine possesses this feature, so there’s no need to worry about a high output start current that’ll distort the project piece before the welding has even started.

In truth, it’s not rocket science. Adjust the amperage to match the metal gauge, thick or thin, account for the composition of the workpiece, be it stainless steel or mild steel, and select an electrode. The connections, as dictated by the machine instructions will need a polarity that corresponds to the stick’s welding characteristics. Note: The TL-195S is best suited for mild steel welding.How To Stick Weld Different Workpiece Thicknesses

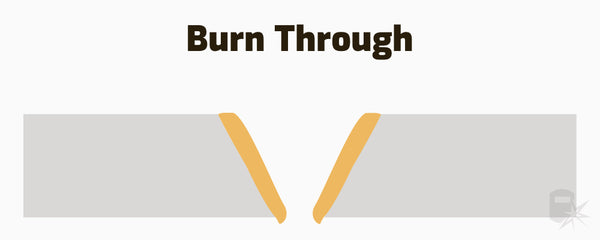

Everything up to this point has been a preamble to the main event. The electrode is fitted, the machine is configured, amperage settings are tuned in, and the technique has been practiced on several pieces of scrap metal. What are the final thoughts before the arc is initiated? Travel speed is one. Working on thinner parts, the weld puddle is “pulled” back faster. The bead lays in a thin line, penetrating shallowly, and there’s no opportunity for thermal energy to accumulate. Remember, too much heat equals warping or burnthrough when working on thin metals. Switching over to a thicker gauge, the project demands a slow travel speed, the better to ensure depth penetration and a strong joint.

-

Travel speed

-

Welding position

-

Arc length

-

Cable polarity

-

Joint prep

-

Single or multi-pass

-

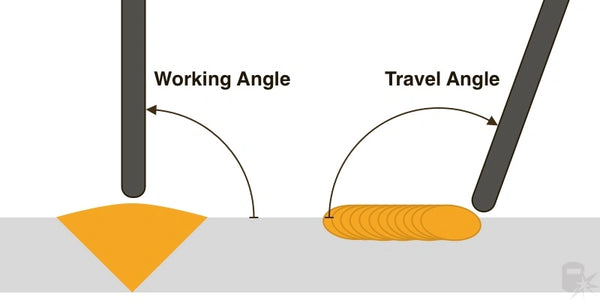

Electrode angle

-

Root pass technique

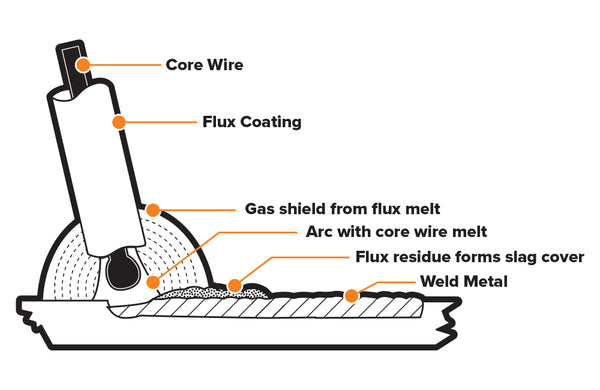

Polarity and travel speed have already been discussed. Let’s move on to the question of arc length. The SMAW machine, utilizing the easy start arc technology built into the Tooliom TL-195S, initiates. The gas shield produced by the flux coating gathers around the weld zone. A low amperage setting and corresponding electrode is configured to match a thin metal part. In this case, the polarity is DCEN and the electrode is a multi-purpose E6010. Manipulating the electrode to an angle of 15° with care, a narrow bead pulls back, the single pass along the prepared surface drops the weld pool moderately deep, but there’s no risk of warping, not with the amperage set correctly and the bead moving at a decent pace. The stick angle and arc length are monitored. Consistency is key. For that skinny metal part, a shorter arc length of ¼” should hit a high-quality sweet spot and keep the arc from straying.

Source: https://weldguru.com/stick-welding-tips/

The goal here is to lay a strong, clean weld bead that has enough thermal energy to fluidize the pool but not so much that it generates non-dissipating heat. Thermal overloads, and this is worth mentioning again and again, will cause parts warping and non-recoverable base metal holes.

On switching over to a welding project with moderately thick metal, there’s a whole new set of issues to manage. The idea that a single pass will produce a strong joint is now less likely. Any welder with even a little amount of experience knows that multiple passes are often necessary when welding thicker metal parts. Starting the project on heavier stock, a root pass provides penetration depth and fusion strength. This time around, the Tooliom TIG/Stick High Frequency Dual Voltage TL-200T 2 in 1 Welding Machine is chosen because of the denser metal. Not only does this machine weld heavy gauge metals with ease, it also operates on high tensile materials, such as stainless steel.

TIG/Stick High Frequency Dual Voltage TL-200T 2 in 1 Welding Machine|Tooliom

After the root pass, which functions like a shelf for further weld passes, that strong foundation is layered with a second and even a third bead until the entire joint is filled. These so-called build-up passes imbue the joint with strength and dimensional uniformity. From the surface of the project piece to the root, the joint delivers optimal robustness and equitable filler conformity.Stick Welding Thickness Management Strategies

Strategy one, to no one’s surprise, is the prep work. The equipment settings and code of the electrode are both locked in by the welder. On the thin sheet metal, mild steel or stainless, flimsy sheets will shift around. A series of strategically placed tack welds hold the parts rock-solid. Is the sheeting grimy or covered in corrosion/ paint? A wire brush or other provided cleaning tool cleans the metal surface and restores it to like-new condition. Next, considering how thin the metal might be, perhaps as slender as 5/64” in overall thickness, a stringer bead technique imparts rigidity and strength while eliminating any chance of parts-deforming heat build-up.

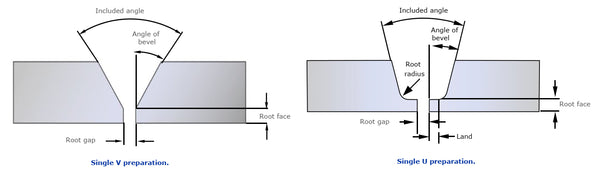

Not surprisingly, thicker metal workpieces require more prep work. The choice of a v-bevel or u-bevel is one matter to weigh, as is the strong backbone of the root pass. Seen from the side, the profile of the bevel narrows as it drops towards the root. The wider top, where the bulk of the fusion material cools, is crucial for maintaining weld strength, ductility and stability. Additionally, the angle of the bevel must be determined to ensure proper penetration and fusion. The welder must also consider the type and size of the filler metal to be used as well as the welding technique that will be employed. All of these factors come together to create a strong and durable weld on thicker metal workpieces.

Weld Bevel

Source: https://amarineblog.com/2019/09/05/groove-design-bevel-preparation/

Finally, between each pass, there’s a cooling phase and slag removal work to carry out. By doing so, distortions in the weld bead are eliminated and a clean, uniform bead appearance is assured. It’s a whole other fabrication discipline, one metal workers sometimes refer to as the joint preparation phase. Fit-up is key. This is where the parts are checked to ensure they have matching geometries. Gaps are not tolerated here, not unless they’re part of a planned bevel. Gaps weaken welds and increase the chance of weld failure. Certain electrodes do incorporate fillers that fluidize faster and fill more aggressively, but optimal fit-ups aim for few if any gaps.

It’s a lot to process, all of those workflow issues associated with welding moderately thick and heavy gauge metals. More depth does seem to equate to more depth penetration planning, hence the need for some metal fabrication skill. Those beveled groove profiles are all part and parcel of the bead penetrating puzzle. Done properly, partnered with weld angle, a good travel speed and machine amperage/voltage setting, we’re making certain of a strong root channel. That sturdy weld foundation then acts as a base for further weld passes, and a categorically robust joint is formed, cooled, inspected and put into service.

The Influence of Different Factors on the Weld

Source: https://www.cruxweld.com/blog/five-steps-to-improving-your-stick-welding-technique/

Sum Up: Stick Weld Different Thicknesses with Confidence

The core of this article is dimensional thickness, not material density. Nevertheless, by adding density, by moving from a mild steel to a high-tensile stainless or carbon steel, a material that’s heat treated and tempered for strength and ductility, then the workpiece becomes that much harder to weld. Higher machine currents are advised when making this switch. Furthermore, heat conductivity profiles can change dramatically when working on stainless steel. If welding on a thin metal part, amperage settings should be adjusted accordingly to account for this change.

Otherwise, it’s a question of weld passes and dimensions. Depth, to be precise, is the dimension in question. A thin base metal part isn’t beginner friendly when using a stick welding rig, but the fast, low-current start cycle built into Tooliom machines will help. It’s more a question of heat dissipation characteristics, though. The high currents generated by this technique aren’t thin metal friendly. Use stringer beads and a faster travel speed to minimize heat and reduce the chances of burnthrough.

Source: https://weldguru.com/common-welding-defects/

Passing above thin metal dimensions, moving up to 5/32” (4.0mm) thick sheets, welders are expected to know how to address certain penetration-relevant bead fusing issues. The key is a good preparation management program, one where a fabricator works to ascertain optimal parts fit-up, groove beveling and a sound multi-pass technique. Cooling phases and slag cleanup routines are just as important here, so take a beat to put in the work between each of those filler passes. After all, thin or thick, moderately dimensioned or heavy gauge, welders need a high degree of adaptability if they’re going to successfully address any penetration-relevant bead fusing issues. Having the right equipment on hand helps, but it’s you, the onsite welder or hobbyist, who needs to adapt on-the-fly to effectively handle various metal thicknesses.

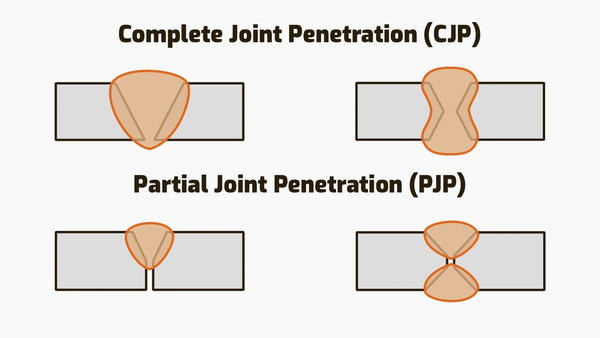

Complete Vs. Partial Joint Penetration

Source: https://weldguru.com/what-is-full-penetration-weld/

One day you’re working on thin sheet metal, perhaps on a worksite that’s installing an air conditioning system, but the next day, well, you could be working on a pressure vessel of some kind or a structurally supportive wall. To make that switch, you’ll need to have all of the knowledge in this article intimately and be able to apply it at a moment’s notice.

A Tabulated Guide to Stick Welding Various Metal Thicknesses

| Topic | Key Points | Additional Details |

| Introduction | Stick welding is popular but challenging when dealing with different workpiece thicknesses. | |

| Electrode Selection | Choosing the right electrode based on workpiece thickness. | Stick codes provide information on core composition and flux coating. |

| Equipment Setup for Workpiece Thickness | Adjust amperage and polarity to match metal gauge; consult equipment manual and datasheets. | Coating/core characteristics affect welding performance on different thicknesses. |

| Arc Starting and Control | Smart equipment settings, like fast arc start, help control welding power and prevent distortion. | Pulsed current control is limited in stick welding, so rely on equipment settings. |

| Welding Different Thicknesses | Adjust travel speed, welding position, arc length, passes, electrode angle, and root pass technique. | Consistency is crucial for quality welds. |

| Cooling and Slag Removal | Proper cooling and slag removal between passes are essential for a clean and a uniform weld bead. | Slag removal prevents defects and ensures a smooth finish. |

| Adaptability | Welders must adapt to various metal thicknesses and apply knowledge effectively. | Knowledge and adaptability are crucial for success in different welding scenarios. |

Effective Stick Welding Techniques for Welding Metals of Various Thicknesses - FAQ

Q: What factors should be taken into account when stick welding different workpiece thicknesses?

A: When stick welding different workpiece thicknesses, you should consider factors such as travel speed, welding position, arc length, cable polarity, joint preparation, the need for single or multi-pass welding, electrode angle, and root pass technique. These factors vary depending on whether you are working on thin or thick materials.

Q: How can you manage the challenges of stick welding with different thicknesses of metal?

A: To manage the challenges of stick welding with different thicknesses of metal, it's crucial to prepare the workpieces properly. For thin sheet metal, tack welds and stringer bead techniques can help prevent heat-related issues. Thicker metal workpieces require more prep work, including selecting the right bevel profile and filler metal. Cooling phases and slag removal between passes are essential to maintain weld quality.

Q: What factors should you consider when selecting the right electrode for stick welding different workpiece thicknesses?

A: When selecting the right electrode for stick welding different workpiece thicknesses, you should consider the thickness of the workpiece. Thicker electrodes are best for welding thicker metals, while thin electrodes are ideal for thin sheet metal. Stick electrode codes, which provide information about core composition and flux coating, can help you make the right choice.