In this article, you are going to learn the basics of Flux-Cored Arc Welding(FCAW).

The MIG, MAG & FCAW are continuous welding processes (not intermittent like SMAW shielded metal arc welding due to the need of charging new electrodes) in which the welding pool is protected from the surrounding atmosphere by using shielding gases (in addition to flux in case of FCAW), which flows from the welding torch on to the piece to be welded.

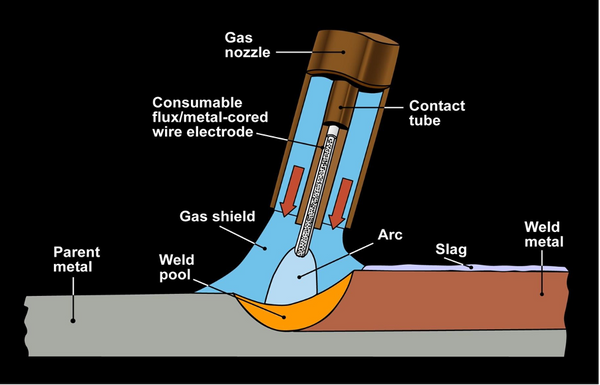

FCAW is an acronym for flux-cored arc welding in which a flux-cored wire (not solid wire as in the case of MIG & MAG welding) is used in welding.

The layout of FCAW processes:

Source: https://shipbuildingknowledge.wordpress.com/2018/04/11/cswip-3-1-question-with-answer-and-explanation-part-22/

As shown, the welding wire is flux-cored or metal-cored. In this process, the molten weld metal is protected by the applied shielding gas which goes to the welding pool through the welding torch and is also protected by the emitted gases coming from the burnt flux. That is why it is sometimes called “OUTERSHIELD” process. That is why it is characterized by the high quality of produced weld metals. This process can also be operated without using shielding gas, and in this case, the protection of the weld pool comes from the flux only. That is why it is called “INNERSHIELD” process which can be used in applications where the setup of shielding gases becomes difficult, like welding at high Heights.

Source: https://smallfarmersjournal.com/basic-welding-for-farm-and-ranch/

FCAW Pros and Cons

FCAW has some Pros and Cons as follows:

| Pros | Cons |

|

|

Basic Equipment for Flux-Cored Arc Welding (FCAW)

Please check out the linked article to get the list of supplies you will need when you are ready to start Flux-Cored Arc Welding.

FCAW Applications

FCAW welding is a semi-automatic process that does not require high skill level like in the traditional TIG, SMAW, and oxyacetylene welding. It is a technique used by beginners as well as professionals. The common areas using this welding process are as follows:

Sheet metal welding

FCAW welding is especially suitable for most types of sheet metals and low alloys in addition to nickel-based alloys. This process is suitable for welding thin metal sheets with high productivity, which is why it is used extensively in sheet metal welding works.

Photo by @migslayerdb

Fabrication of pressure vessels and steel structures

FCAW welding is used in almost the entire welding industry. This welding process is approved to be used in steel structure fabrication and in pressure vessel fabrication. That is why the largest users are the heavy and metalworking industries. These include the shipbuilding industry, steel structures, pipelines, and pressure vessels.

Source: https://www.supplyht.com/articles/104199-what-you-need-to-know-about-welding

Automotive and metalwork industries

The FCAW welding process is used on a large scale in the automotive industry due to its high productivity and ease of use, so beginners and professionals can use it without any problems. It remains very popular with metalwork professionals in the automotive industry.

Source: https://www.themechanicdoctor.com/how-to-weld-auto-body-sheet-metal/

If you are interested in the difference between MIG, MAG and Flux-Cored Arc Welding(FCAW), please check the linked article MIG, MAG & Flux-Cored Arc Welding(FCAW)Explained.